kubota hydraulic cylinder seal kits cost | Wholesale-in-China Expert Guide

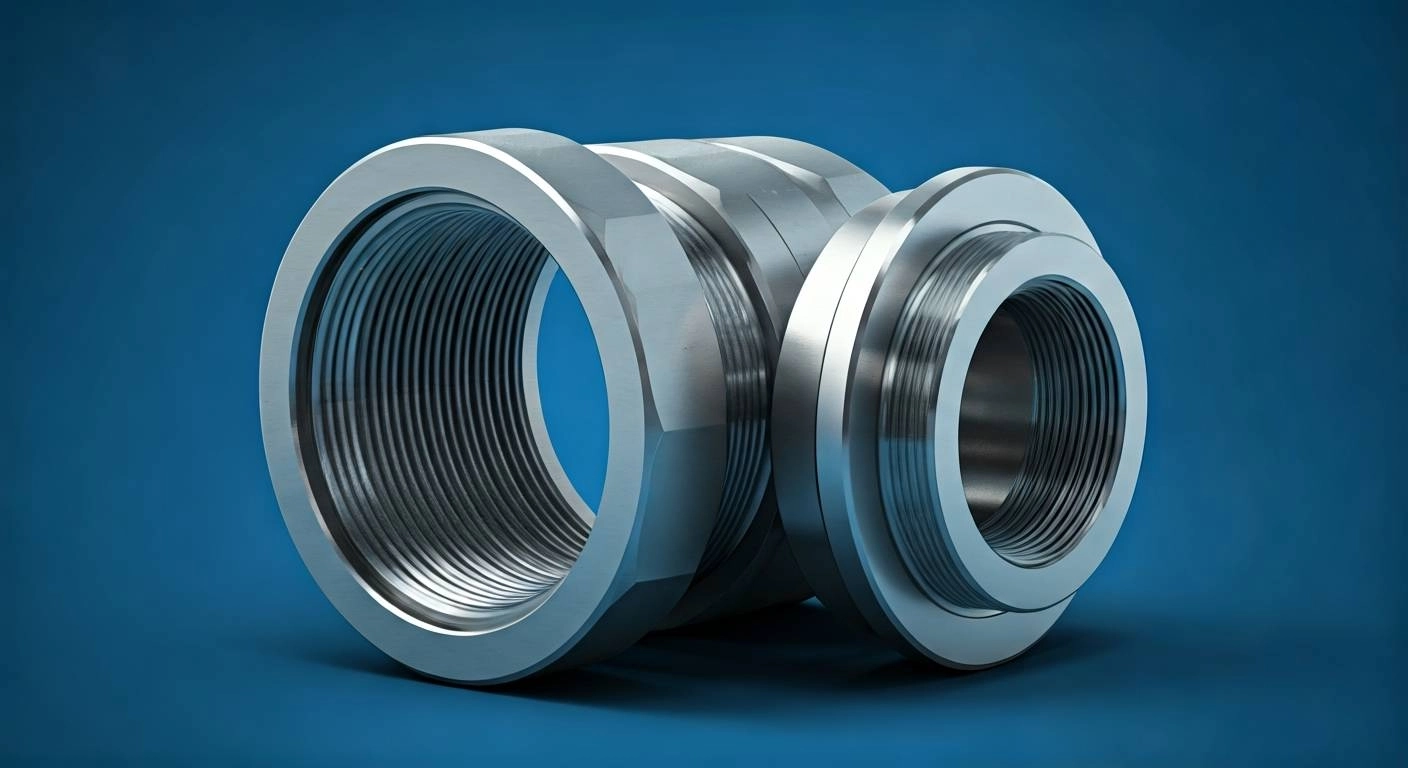

Kubota Hydraulic Cylinder Seal Kits: Cost, Common Questions, and Buying Guide

Sourcing hydraulic cylinder seal kits for Kubota machinery can be complex. This guide addresses common questions and provides crucial information for China sourcing industry buyers to make informed purchasing decisions.

What factors influence the cost of Kubota hydraulic cylinder seal kits?

The cost of Kubota hydraulic cylinder seal kits is influenced by several key factors:

- Material: The material used in the seals directly impacts the price. Common materials include Nitrile (NBR), Viton (FKM), Polyurethane (PU), and PTFE. Viton seals, known for their high-temperature resistance, are generally more expensive than NBR seals.

- Size and Complexity: Larger and more complex seal kits with multiple components and intricate designs will typically cost more.

- Brand and Manufacturer: Genuine Kubota seal kits often command a High Quality price due to brand reputation and quality control. Aftermarket kits from reputable manufacturers can offer cost savings.

- Quantity: As with most products, purchasing in larger quantities often results in a lower per-unit cost.

- Supplier Location: Prices can vary depending on the supplier's location and associated shipping costs. Sourcing directly from China may offer cost advantages, but it's crucial to consider shipping times and potential import duties.

- Seal Type: Different seal types (e.g., rod seals, piston seals, wiper seals) require varying manufacturing processes and materials, affecting the cost.

What are common problems or reasons to replace Kubota hydraulic cylinder seals?

Hydraulic cylinder seals are subject to wear and tear, leading to common issues such as:

- Leaks: The most obvious sign of seal failure is hydraulic fluid leakage around the cylinder rod or piston.

- Reduced Performance: Worn seals can cause a loss of hydraulic pressure, resulting in slower or weaker cylinder movement.

- Contamination: Damaged seals can allow contaminants (dirt, debris) to enter the hydraulic system, leading to further damage and accelerated wear.

- Drifting: Cylinders may drift or move unintentionally due to internal leakage caused by seal failure.

- Physical Damage: Seals can be physically damaged by overpressure, extreme temperatures, or incompatible hydraulic fluids.

Where can I find reliable suppliers of Kubota hydraulic cylinder seal kits in China?

Finding reliable suppliers requires careful research. Consider these options:

- Online B2B Marketplaces: Platforms like Alibaba, Made-in-China.com, and Global Sources host numerous suppliers of hydraulic seals and cylinder kits. Carefully vet potential suppliers by checking their business licenses, certifications (e.g., ISO 9001), and customer reviews.

- Trade Shows: Attending trade shows focused on hydraulic components and agricultural machinery can provide opportunities to meet suppliers in person and assess their capabilities.

- Referrals: Seek referrals from other businesses in the industry who have experience sourcing hydraulic components from China.

- Wholesale Platforms: Consider wholesale platforms like Wholesale-in-China, which can connect you with verified suppliers and provide additional support with quality control and logistics.

How can I ensure the quality of Kubota hydraulic cylinder seal kits from China?

Quality control is paramount when sourcing from China. Implement these measures:

- Supplier Audits: Conduct thorough audits of potential suppliers to assess their manufacturing processes, quality control systems, and testing capabilities.

- Sample Testing: Request samples of seal kits for testing before placing a large order. Test for material properties, dimensional accuracy, and performance under pressure.

- Third-Party Inspection: Hire a third-party inspection agency to conduct pre-shipment inspections to verify that the products meet your specifications.

- Clear Specifications: Provide suppliers with detailed specifications, including material requirements, dimensions, tolerances, and performance standards.

- Contractual Agreements: Establish clear contractual agreements with suppliers that outline quality standards, warranty terms, and dispute resolution mechanisms.

- ISO Certifications: Prioritize suppliers with ISO 9001 certification, indicating a commitment to quality management systems.

What types of materials are commonly used in Kubota hydraulic cylinder seals?

Common materials used in Kubota hydraulic cylinder seals include:

- Nitrile Rubber (NBR): Offers good resistance to petroleum-based oils and fuels, making it a cost-effective option for many hydraulic applications.

- Viton (FKM): Provides excellent resistance to high temperatures, chemicals, and ozone. Suitable for demanding applications.

- Polyurethane (PU): Known for its high tensile strength, abrasion resistance, and elasticity. Often used for wiper seals and rod seals.

- Polytetrafluoroethylene (PTFE): Offers exceptional chemical resistance and a low coefficient of friction. Used in applications where minimal stick-slip is required.

- Ethylene Propylene Rubber (EPDM): Provides good resistance to water, steam, and phosphate ester hydraulic fluids.

Selecting the correct material depends on the specific application, operating temperature, hydraulic fluid type, and pressure requirements.

Related Posts

Stay informed with our latest news and updates.

Bringing you breaking news and curated stories every day. Be the first to know the latest industry news

Wholesale-in-China

Wholesale-in-China

Wholesale-in-China